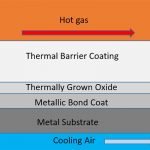

What You Should Know About Thermal Barrier Coatings

Thermal spray coating can be used on parts and new components to give them a more durable, more robust finish. The application of a thermal barrier coating is also the best way to fix worn out, corroded or damaged surfaces. The purpose behind services that provide protective coating processes is to lessen performance detriments like corrosion and wear. These detriments can greatly affect a company’s bottom line by lessening their productivity and overloading their maintenance crews.

Thermal barrier coatings are applied by different processes. Some of those are discussed below.

Processes For Thermal Spray Coating

The following are processes through which thermal barrier coatings can be applied to your company’s products, components, surfaces, and parts:

- Spray and Fuse Hard Facing – To apply a vast array of materials onto a substrate, the utilization of a combustion powder spray gun is required for this process. The part is heated after the coating has been sprayed upon it. This allows for a true metallurgical bond. A coating hardness up to 80 Rc can be achieved with this process.

- Plasma Spray Coating – Of all the thermal spray processes, this is the most flexible. A protective coating is provided by the spraying of a heat softened or molten material onto a surface. Using this type of technology, nearly any metal, cermet, or ceramic can be applied to any number of materials providing minimal distortion of the substrate and incredible bond strength.

- Metalizing – When referring to the process of thermal spray coating being applied to metal product surfaces, it is generally referred to as metalizing. Metallic coatings with functional, decorative, or protective purposes are the result. Additionally, these coatings are highly versatile, efficient, and long-lasting. The three types of metalizing processes are combustion wire spray, combustion powder spray, and electric arc spray.

- HVOF Coating – This stands for high-velocity oxygen fuel which is a process that produces carbide, high-quality metal, and various specialty coatings. Thanks to this type of coating technology, many industries are afforded the ability to extend the range of applications and use unique coating properties that, not so long ago, could only be achieved by processes of proprietary coating.

Choosing A Coating Material Wisely

It is essential that before beginning any thermal spray coating process, one determines which material will be appropriate for application to the substrate. What difference does the thermal spraying material make? With the correct material, a company can cut down on operational costs and downtime. What this means to the company is improved efficiency and an increase in overall productivity. Maintenance teams will be grateful as well because part replacement and excessive maintenance will be lessened. Part failure, though it may be caused by some other unpredictable circumstance, will no longer be a result of excessive wear, corrosion, abrasion, etc. Using the right kind of protective coating and the proper application process means an overall improvement to a company’s bottom line.

At A&A Coatings, our staff is ready to assist you and fully capable of handling your protective coating needs. If you have questions or would like to find out more about how thermal barrier coatings can improve your company’s bottom line, please contact us today.