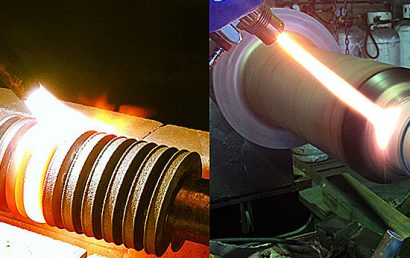

Thermal Spray Process Showcase: Roll Grinding

At A&A Coatings, we offer a comprehensive range of machining and grinding services to many companies in a wide range of industries. Apart from undercut pre-machining and other finishing services, one of our specialties is roll grinding and machining. With more than seventy years of industry-specific experience, you can always benefit from our services that will always be delivered with excellence.

What is Roll Grinding and Machining?

The process of generating a new surface and removing material for high precision rolls is called roll grinding. Compared to other process such as milling or turning, the desired surface finish and precision can be obtained much more effectively through grinding a precision roll. At A&A Company, we offer a complete range of turn-key thermal spray coating services, including polishing, machining and finish grinding. In addition, our roll grinding capacity allows us to grind base substrates of almost any metal as well as coatings up to the hardness of tungsten carbides and even ceramics.

What are the Capabilities of Our Roll Grinding Services at A&A Coatings?

First and foremost, our roll grinding technology is able to refinish hardened steel rolls that were damaged, using precision grinding techniques. Our roll grinding services also offer our clients a full range of precision crowning options, including straight-tapered, radial and parabolic. At A&A Coatings, our roll grinding capabilities also ensure that your high precision rolls are finished in bearings, and can be unpacked from the shipping box quickly and transferred straight to your line.

A&A Coatings is also a comprehensive thermal spray coating and roll grinding service shop that provides stellar grinding services to our clients in various industries, including roofing, steel, plastic, converting, non-woven and paper.

What are the Benefits of Our Roll Grinding Services?

When A&A Coatings executes roll grinding procedures for our clients, they can rest assured with fast and accurate grinding that will happen within shutdown intervals that are planned. In addition, our equipment runs reliably and will ensure cost-effectiveness in all productions as well as extending roll cover running times.

Roll Grinding Equipment that A&A Coatings Use

A&A Coatings implements up-to-date expertise and uses the latest equipment to achieve strict dimensional tolerances and meet all required surface finish requirements. We have a great array of advanced grinding machines that will easily meet the specific needs of our customers. We are also continuously improving our grinding technology, which in turn allow us to deliver better roll cover performance. Here are some of our roll grinding equipment:

- Mattison Surface Grinder

- Craven Roll Grinder (CNC)

- SMTW Cylindrical OD Grinder

Materials that We Handle

Roll grinding services provided by A&A Coatings cover a great range of materials, which include:

- Rubber

- Tungsten

- Carbide

- Steel

- Stainless steel

- Chrome

- Ceramic

- D2 hardened steel

- 52100 Hardened Steel

- Chilled Cast Iron

- Brass

If you plan on using our roll grinding services to grind coatings of varying hardness, do not hesitate to contact A&A Coatings today via phone or email!