Thermal Sprayed Furniture: An Intriguing Project By Max Lamb

When most people think of the thermal spray process, they think of protective coatings being applied to parts or components in order to prevent excessive wear, corrosion, and abrasion; or a handful of other reasons. It isn’t likely that anyone who has used or been introduced to the benefits of thermal spayed protective coatings would envision them as a means of creating furniture. And yet, that’s exactly what a man named Max Lamb has done.

Who Is Max Lamb?

Born and raised in England (more specifically, Cornwall), Max Lamb grew up in a beautiful (if not isolated) section of the UK. The majority of his time was spent in an environment where physical labor was celebrated. He could frequently be fun on his grandfather’s farm, digging in the garden belonging to his parents, in the woods, or on the beach.

These days, he is also a furniture crafter. Due to influences from his military upbringing (according to Mr. Lamb himself), his latest obsession with design has taken a definite, if not intriguing turn. This fresh approach to furniture is responsible for securing his furniture a spot in Kvadrat and Acne Studios.

The Thermal Spray Collection

Rather than using thermal spraying as a method of protective coating for parts and components, Max Lamb has put it to work as a production process. A number of projects have been completed by this furniture artist using thermal spray. He insists that the first one was merely an experiment, but ended up on exhibition in France. Following that, for New York’s Acne Studios, he did an entire collection. The collection showcased at the Madison Avenue store. What does he thermal spray? All sorts of things including planters, vases, shelving units, tables, chairs, and more. And all are done using an identical thermal spray technique.

A Technique All His Own

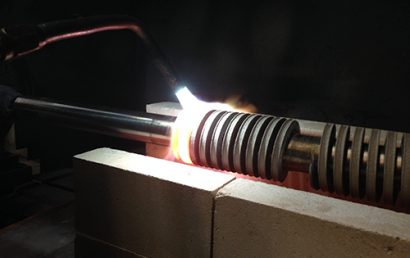

Mr. Lamb says that his thermal spring process is a combination of welding and spray painting. He understands that it is usually used in architecture and engineering for piping or steel. Specifically for this furniture project, thermal spray workers were required to tweak their technique. Initially, he did not do the spraying himself. Doing it inappropriately causes shapes to become distorted and the polystyrene to melt. There’s a definite skill to thermal spraying.

The resulting metal surface for his furniture has integrity and quality. The thicknesses are built up over time to a precise level. He creates the forms, and the object is given its structure by the sprayed material. People often look at his pieces and say out loud, ”How did he do that?” And he’s very comfortable with that.

What also results from this intriguing technique of furniture creation doesn’t necessarily fit into some people’s idea of desirable furniture. He is not concerned as much with a chair that is practical, lightweight, ergonomic, or comfortable. It is, however, designed to have a functionality, personality, excitement, and visual intrigue. Knowing full well about ergonomics and form, he chooses to break the rules.

The Drawing Board

Max Lamb is not one for preparation or sketches. He prefers a hands-on approach, opting for skipping steps like sketching and drawing, and going right to creating. Rather than a sketchbook, he simply creates his materials. Communicating on paper is something he finds impossible. “Let’s just make it instead of drawing it.” He states that this is because he is a designer as well as a maker. He enjoys the expediency, spontaneity, speed, and freedom of thermal spraying. The project, he states, is a demonstration of a three-dimensional way of communicating his designer/maker qualities.

Aside from being an innovative medium used by this artist/furniture maker, the thermal spray process is the ideal way to protect parts, components, machinery, products, and other substrates from excessive wear, corrosion, abrasion, erosion, etc. If you feel that your company could benefit from such a process, contact us at A&A Coatings today.