Understanding Thermal Spray Coatings For Offshore Structures & Equipment

Offshore drilling operations present unique challenges with respect to corrosion and wear. Our Thermal Spray Coatings are ready to meet these challenges and provide long lasting solutions.

Wear and Corrosion Resistance

Wear and Corrosion are among the biggest challenges facing offshore drilling structures which can be eliminated or mitigated with the use of Thermal Spray Coatings. For many years, aluminum coatings have been prominently used to protect offshore platforms from atmospheric and salt water corrosion. Additionally, many carbide and ceramic coatings have been used to protect components from wear. Thermal sprayed aluminum or TSA is often combined with a paint coating system to provide much needed corrosion protection while tungsten carbide, alumina-titania ceramic and other materials are applied, ground and polished to resist wear and abrasion. You will find out more about those applications below.

Common Parts Found in Offshore Applications

Gate valves have been found to be extensively used in the offshore oil industry. These valves are chosen because they have the ability to control and contain high flow rate and high-pressure fluids. The types of protections required under this circumstance include abrasion and erosion resistance. Sand is present within the hydrocarbon fluid, and surface regions of seal faces and valves could risk becoming damaged without adequate protection.

The cost of repairing and replacing such valves is usually high however the use of coatings to resist wear and abrasion can minimize these costs. In this case, WC-base coatings are highly opted for because they are better at protecting the sealed surfaces. HVOF-applied WC-CoCr coatings, for example, offer a favorable combination of high fracture toughness and strength/hardness.

Other Parts found in offshore applications which must operate reliably under extremely harsh conditions and benefit from the wear and corrosion resistance of thermally sprayed coatings are:

- Pipes

- Hydraulic Systems

- Exposed Structures

- Drill Bits

- Sensor Housings

- Separation Systems

- Riser Tensioner Rods

- Mandresls

- Stabilizers

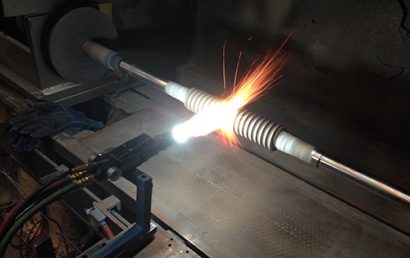

Why the High Velocity Oxygen Fuel (HVOF) Process?

Among the leading coatings on the market are HVOF coatings which have been gaining considerable momentum in terms of becoming a viable alternative to hard chrome plating for a great array of applications including Drilling and pumping equipment. HVOF Coatings are dense and can be extremely wear resistant. In addition, parts such as safety valves, packers, heat exchangers and separators, sucker rods, mud pumps, blowout preventers, chokes and other types of down hole tools benefit from hard metal and carbide-base coatings applied via the HVOF process.

Plasma Sprayed Alumina-Titania Ceramic Coatings are also Used to Provide Corrosion and Wear Resistance at the same time

Plasma sprayed alumina-titania ceramic coatings are applied onto offshore hydraulic components and other parts which require the combination of both Wear and Corrosion resistance. Coincidentally, the U.S. Navy also uses this combination of coating material to prevent corrosion and wear on a myriad of different components such as piston rods and valve balls.

Spray & Fuse Hardfacing Coatings in Offshore Applications

Another extensively used coating for the offshore drilling industry is the family of spray and fuse coatings. These coatings can protect parts such as drill bit stabilizers from erosion, impact and even severe abrasion. If the wear properties of the self-fluxing metal matrix of a structure need to be enhanced, WC particles are added. Other capabilities of these coatings include:

- Reducing wear of screw conveyer surfaces in drilling fluid separators

- Reducing wear of internal/external radial bearings of drive assemblies for mud motors (Note: these motors are used in directional drilling applications)

Want to know more about suitable coatings for offshore applications? Don’t hesitate to contact A&A Coatings today.