Why Industrial Coating Services Are Essential

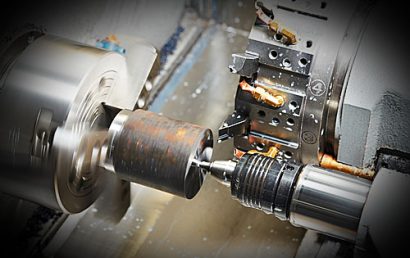

Contractors who apply industrial coatings provide the technology, processes, and materials needed for application in concrete and steel industries (among others). The process of applying this protection/coating on parts, components, machinery, etc. uses a specialized paint (of sorts) or materials that provide a barrier.

Why Use Industrial Coating?

This coating process has many purposes:

- Fights against corrosive or rusting elements when applied to surfaces, thereby assuring a longer life for whatever component they are applied to.

- Not only can parts last longer with protective coating, they can be made to look better, longer.

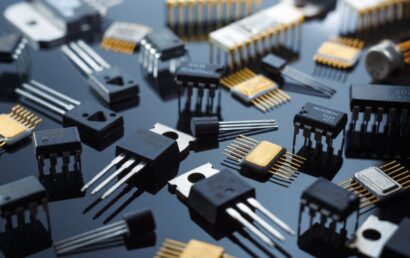

- Sensitive materials, when coated appropriately, can remain free of dust, debris, and clear.

- Corrosion can be completely averted with the use of the proper protective coating.

Industrial Coatings – the Basics

Various substances and essences go into the mixtures that make up industrial coatings such as one known as Xylan. PTFE, FTP, PFA, fluoropolymers, and other components can mix with polyimide and polyamide binder resins (such as dimethylformamide, ethyl acetate, methyl, xylene, etc.) to make the resulting coating process exceptionally strong. Strength is needed to ward off unwanted materials and effects and protect the parts or components to which the coatings have been applied.

Today, all kinds of fields are making use of and applying industrial coatings. First and foremost, these coatings are used in many industrial facilities for a somewhat surprising characteristic – they provide a certain level of a fire resistance. The polymers involved in the coating responsible for this characteristic include polyurethane and epoxy. Also involved in the creation of this material is the utilization of fluoropolymers.

Where steel is made, the above-mentioned substances are invaluable. A smooth finish is provided to the surfaces of processed steel through the use of industrial coatings.

Additional Coatings

Phosphate, PVD coating, and zinc are also substances utilized in various types of industrial coatings. Industrial coating contractors will apply and mix together these substances to the specific needs of the client.

These particular substances are frequently used on the surfaces of alleys, hallways, and walkways that receive a high amount of foot traffic. Industrial coatings of this caliber can also be found in kitchens, hospitals, schools, and more. Not only do these kinds of walkway coatings prevent slipping and injuries, they are additionally aesthetically pleasing because of the smooth finish provided. Surprisingly enough, however, though appearing smooth, they create a considerable level of friction. This means that items being transported via these walkways stand less of a chance of balance loss, wobbling, etc. Maintenance and cleaning of these surfaces is easier thanks to the coatings, as well.

With all of the benefits that industrial coatings and the contractors who apply them offer, it’s hard to imagine why some industries or companies are hesitant to find out more about them.

One of the best decisions a company can make is the contracting of a reputable, reliable, and knowledgeable industrial coatings service. At A & A Coatings, we have been at the forefront of the thermal spray industry since 1944. For numerous industries and applications, we provide an extensive array of coatings. Contact us today and ask a seasoned professional what sets A & A Coatings apart from the rest of the industrial coating industry.