What You Should Know About Precision Powder Coating

Precision powder coating is a high-performance finishing process that combines accuracy, consistency, and durability in one application. By applying a fine powder through electrostatic charge and curing it under heat, manufacturers achieve smooth, uniform surfaces that last under demanding conditions. For industries where every millimeter matters, this process has become a trusted solution for protection and appearance. Understanding how it works and why it matters can help you make better decisions for your next surface treatment project.

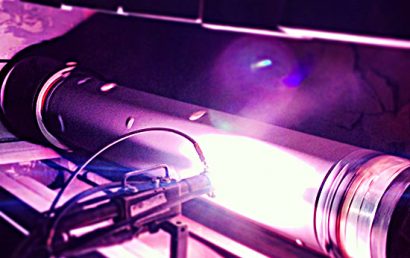

How Precision Powder Coating Works

The process begins with surface preparation, where contaminants are removed to help the powder bond effectively. The part is then electrostatically coated with fine powder particles, which cling evenly to the surface. Once applied, the coated item moves into a curing oven where the powder melts and forms a continuous, durable film. Precision depends on controlling film thickness, avoiding edge buildup, and achieving uniform coverage. The equipment setup, curing temperature, and application method must all align perfectly to produce a consistent finish that performs to specification.

Key Benefits of Precision Powder Coating

One of the greatest advantages of precision powder coating is its exceptional durability. The cured layer protects against abrasion, corrosion, UV damage, and chemical exposure. The process is also environmentally friendly since it produces no volatile organic compounds and allows unused powder to be reclaimed. You can achieve thicker coatings in a single pass without the risk of sagging or dripping. For manufacturers, this means fewer reworks, less waste, and lower long-term costs. With a wide selection of colors, gloss levels, and surface textures, powder coating also provides impressive design flexibility without compromising protection.

Challenges and Best Practices

Maintaining precision requires expertise and control during each step of coating. Surface preparation is critical because even a trace of oil or dust can lead to poor adhesion. Temperature control during curing must be monitored carefully to prevent overbaking or undercuring, both of which can affect finish quality. Masking is also a key factor when specific areas must remain uncoated. Skilled technicians use proper materials and procedures to produce consistent results, keeping coatings uniform and within tight tolerance limits across large or complex parts.

Applications Across Industries

Precision powder coating supports performance across a range of fields. Aerospace engineers use it for high-stress components exposed to heat and friction. Automotive manufacturers depend on it for frames, wheels, and structural parts that demand both strength and aesthetic appeal. Electronics and medical equipment producers rely on its insulation and chemical resistance properties. Industrial facilities also apply it to machinery and tools to extend their service life. Each application benefits from consistent thickness, enhanced surface integrity, and long-lasting protection.

Work with a Trusted Leader in Surface Coatings

Precision powder coating continues to redefine quality and reliability across industries that require accuracy and endurance. At A&A Coatings, we have spent decades helping clients improve performance and extend component life through advanced coating technologies. Our team combines technical skill with proven materials to meet your unique specifications.

If you need precision, durability, and trusted results, reach out to us today to discuss how our coating services can support your next project.