Can Thermal Spray Coating Prevent Pump Cavitation?

Man has been fearing and fighting cavitation since the genesis of the modern centrifugal pump approximately 300 years ago. Cavitation refers to the formation of minute vapor bubbles in a liquid because of reduced pressure pockets. It’s akin to the bubbles you see in boiling water; however, instead of heat creating the bubbles, cavitation is the result of a difference in pressure caused by fluid that moves through the pump. Such a phenomenon can occur in any kind of liquid. Significant damage can happen when these bubbles form and explode in the very tight areas of a pump. Thankfully, thermal spray coating can prevent pump cavitation. Let’s explore this further below.

Is There A Way to Prevent Cavitation?

The best solution to curb cavitation is by allowing pumps to function at their engineered flow rate and to be aware of the pump curve. However, this isn’t always possible; but you can also make sure the pump is of a durable material that can highly resist cavitation damage. However, it is expensive to purchase a pump that is made of these robust materials. One of the solutions to tackle this is to choose a more affordable pump and then use premium quality materials to apply thermal spray coating on the surfaces of the pump that might be affected by cavitation damage.

The Designed Solution

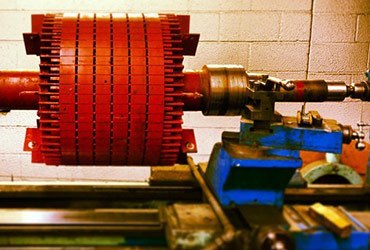

Thermal spray is a coating procedure akin to spray painting, except that it uses molten metal. What happens here is that a coating material of choice is heated and applied through the use of gases and air to the casing, pump impeller, and other high-wear areas. Thermal spray may be used on a fresh pump to mitigate corrosion, cavitation damage or material erosion, or it may be paired with welding and machining services to fix elements that have been damaged in previous operations. Thermal spray is used to fix numerous pump components.

Thermal spray coatings have been shown to be highly robust in withstanding cavitation. But they are not necessarily ductile. The regular coatings can offer some protection against risks of cavitation but could get destroyed quickly when exposed for prolonged periods. High Velocity Air Fuel (HVAF) is a specific form of thermal spray that ensures coating materials can be sprayed near their melting points. This creates a more ductile and uniform coating. The coating of HVAF provides stronger cavitation protection as compared to its high-velocity predecessor, HVOF. HVAF is a more affordable and quality alternative to lengthen the life of pumps.

Using The Necessary Protection

Cavitation is always a strong factor that challenges a pump’s lifespan, but there are various solutions to help you tackle this. It’s like accidentally dropping your smartphone; it is probably going to occur a couple of times in your life. Hence, to fix this, you protect your phone with a phone case to extend the life of your phone and guard it against worse damage. By thermal spray coating the components of a pump, you can be assured that if any cavitation were to happen, your pump will definitely be able to withstand problems longer.