Exploring The Various Kinds Of Wear

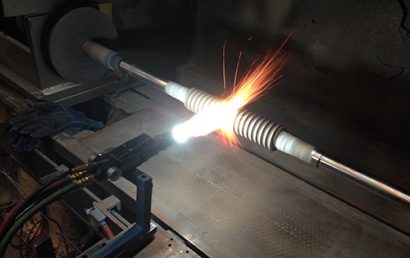

More and more industries are making the intelligent, informed decision to use thermal spray to apply protective coatings to their machinery, components, parts, and more. But why is this process so very valuable? The word “protective” gives it away. Without the coatings applied through thermal spray, machinery, components, parts, etc. would not be shielded against wear and other damaging conditions. That means increased downtime, increased maintenance costs, and a decreased bottom line. This is simply unacceptable when there is such an easy solution at hand.

Wear Variations Requiring Protective Coating

So how does one know what kind of protective coating, or hardfacing, to use? It all depends on what kind of wear the parts, components, etc. are exposed to. And, something else to think about is that there can be more than one kind of wear affecting a part or piece at any given time. With all of this in mind, let’s take a look at some typical types of wear. Most commonly the factors (or modes) encountered are the following:

- Cavitation

- Heat

- Corrosion

- Erosion

- Galling/Adhesive

- Impact

- Abrasion

Cavitation

This is caused when, under pressure and within a liquid, vapor bubbles collapse. This will cause spalling (through fatigue) on a metal surface over time.

Heat

Particularly when combined with other types of wear, accelerated degradation and/or break down can be caused by a softening of the metal caused by excessive heat.

Corrosion

As a result of a chemical reaction, metal deteriorates because of corrosive wear.

Erosion

Erosive wear occurs when liquid or air suspended abrasive particles wear away a surface. A good example of erosive wear is what happens as a result of water and sand flowing through a pipe.

Galling

Adhesion wear and galling wear are similar with the more extreme version of the two being galling. When two metallic surfaces slide together and a transfer results, this can cause galling. This is particularly applicable when there is no lubrication present. One example of galling wear would be the surface of a bearing with no lubricant (or too little lubricant) on the processing roll used in a steel mill.

Impact Wear

When a metal deforms and is worn away leading to cracking and metal fatigue, and this is a direct result of high-impact forces, it is referred to as impact wear. Ground engaging tools such as bucket teeth see both abrasion and impact wear.

Abrasion

When friction causes the wearing-away of a surface, this is referred to as abrasion. Frequently scraping or grinding is involved. There are three categories of this, the most common type of wear:

- Gouging abrasion is frequently caused when impact loading, high stress conditions wear away metal surfaces.

- High stress abrasion occurs when material (metal) is removed by the polishing of an abrasive; metal is worn away.

- Low stress abrasion occurs when material is removed by the polishing of an abrasive, but not to the depth or severity that results during high stress abrasion. It is more of a surface condition.

If you are unsure what kind of wear your company or industry deals with on a regular basis, and what can be done to protect against it, contact the experts at A & A Coatings. We have knowledgeable and experienced staff members standing by to help you with all your thermal spray and protective coating needs. Contact us today to speak to a professional.