How Is Tungsten Carbide Currently Being Used?

All throughout the world, there are numerous applications where metal compounds are being used. But compared to any one of them,

tungsten carbide possesses the most unique attributes. Frequently used in jobs such as building applications, precise grinding and milling, jewelry production, and more, the addition of these materials can help create a pitting, scratch, rust, and heat resistant alloy.

The Milling Industry

For the manufacture of some mill inserts, finish mills, and other mill merchandise, tungsten carbide is used. In the milling and grinding industry, For applications that yield everything from the finest powder to coarsely grated material, tungsten carbide is preferred because it can be simply molded while remaining extraordinarily tough.

Tungsten Carbide’s Newest Application

Every day, tungsten carbide gains popularity for its newly built jewelry production reputation. In the crafting of jewelry such as earrings, pendants, and rings, it is a desirable alloy thanks to its extreme hardness. Additionally, it is stunningly gorgeous when polished appropriately!

All the rage, as of late, are engagement and wedding rings made from tungsten carbide. Because, compared to gold, it is less expensive, it is exceptionally popular with frugally minded individuals or those on a tight budget.

The Mining Industry

Possibly more than any other industry, numerous building applications use drilling tools created from tungsten carbide. Cutting tools, drill bits, and other mining equipment utilizes approximately 65% of today’s tungsten carbide supply. Due to its resistance to wear and tear, as well as its hardness, in mining applications, it is the preferred material – even over stainless steel.

The hardness of tungsten carbine is only exceeded by diamond. In some applications, the hardness offered coupled with its conductivity make tungsten carbide even more alluring. What’s more, it can be melded with other metals, sharpened to precision, and molded into seemingly limitless shapes.

Tungsten Carbide Combinations

Composite supplies and specialized alloys are created when tungsten carbide is combined with other metals. To make components that can be utilized in applications such as the aeronautical market, radiation shielding supplies, industrial gear generating, electronics, and more industrial building situations, it may be joined with copper, silver, iron, and nickel.

Further Tungsten Carbide Benefits

Periodically, regardless of the benefits of tungsten carbide, components made from it will eventually need replacing. The good news here is that carbide is extremely recyclable. There are, in fact, recycling facilities that do just that. These days, if something is recyclable, it is preferable, with many industries concentrating highly on “going green”.

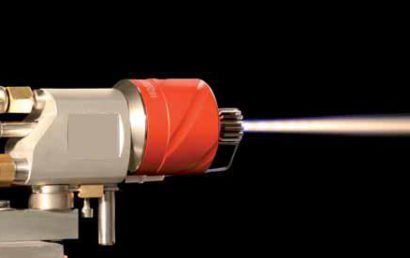

The mechanical and thermal attributes of tungsten carbide, combined with its durability, high wear resistance, and other attributes make it one of the most desirable materials in the industrial marketplace.

At A & A Coatings, we are exceedingly familiar with tungsten carbide and, where appropriate, utilize it in our thermal spray process. If you would like to find out more about how today’s thermal spray coatings can protect your components, machines, surfaces, and your businesses’ bottom line, contact us to speak to one of our knowledgeable representatives.