How To Determine The Right Temperature For Powder Coating

Achieving a strong, durable, and visually appealing finish depends on selecting the correct powder coating temperature. When you apply powder coating to metal or other materials, the curing process is what transforms the powder into a smooth, protective layer. Using the right temperature is essential for creating a consistent finish, preventing defects, and ensuring the coating adheres properly.

Understanding the Role of Temperature in Powder Coating

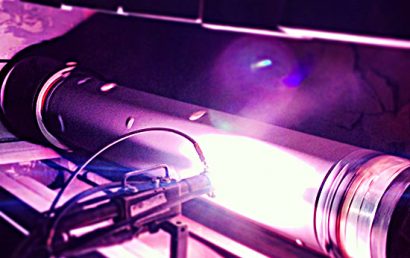

Powder coating involves applying a dry powder to a surface and then heating it until it melts and bonds to the material. The temperature controls how well this coating flows and hardens. If the part is not heated enough, the coating may remain soft or uneven. If the temperature is too high, the coating can discolor, over-cure, or lose its strength.

Each powder coating material has its own recommended curing range, usually between 350°F and 450°F. The goal is to maintain a steady part temperature long enough for the powder to reach full cure. Your coating system’s oven type, airflow, and part thickness all influence how quickly the surface reaches this temperature.

Factors That Affect the Ideal Curing Temperature

Several factors determine the right temperature for your application. The type of powder material is one of the most important considerations. Epoxy-based powders cure at lower temperatures and are often used for indoor applications. Polyester and hybrid coatings can handle higher heat and are common in outdoor environments where weather resistance is needed.

The material of the substrate also affects curing. Thick steel parts take longer to reach curing temperature than thin aluminum pieces. Oven calibration plays a major role as well. Inconsistent oven heat can create uneven results across batches. It is useful to perform regular temperature checks using thermocouples or infrared sensors to make sure the part itself, not just the air inside the oven, is reaching the correct temperature.

Common Problems Caused by Incorrect Temperature

When the curing temperature is too low, the powder may not fully melt, leaving a dull or rough texture. It can also result in poor chemical resistance or coating that easily chips or scratches. In contrast, excessive heat can cause yellowing, loss of gloss, or brittleness. Overheating can also weaken adhesion between the coating and the substrate, leading to premature failure.

You can avoid these problems by following the powder manufacturer’s specifications and verifying the part temperature throughout the process. Keeping consistent oven cycles and avoiding sudden temperature fluctuations will help you produce coatings that maintain their finish and protection over time. This attention to detail will improve both the appearance and performance of your coated parts.

Best Practices for Consistent Results

To maintain quality, preheat your oven before placing the parts inside, and make sure that airflow is balanced to distribute heat evenly. Allow each part to remain at curing temperature for the full recommended time before cooling. If your process involves different materials or coating types, document the exact settings for each to maintain repeatable results.

At A&A Coatings, we offer advanced coating solutions that help your equipment and components perform reliably under demanding conditions. Our expertise in material selection and processing can help you achieve consistent, high-quality finishes while reducing downtime and maintenance costs.