How To Improve Efficiency Of Compressors

When it comes to the performance of a compressor, a major impact can be felt if surface roughness is present. This kind of condition can adversely affect the efficiency of compressors. Performance reducers such as fouling and corrosion are not uncommon. But there is a solution. You can now increase the life of your compressor and improve its efficiency through compressor coatings.

Who Uses Compressors?

First of all, let’s take a look at what kinds of compressors are out there and who makes the most use of them.

There are several grades of compressors which can be broken down into the following:

- Industrial Grade – large-scale manufacturing

- Professional Grade – highly pressurized air and a lot of power

- Consumer Grade – Single stage or pancake model

Compressors have carved out a definite niche in this world. Whether they are used at home, by small businesses, or in major industries, they are a part of our everyday lives. The following are places where compressors can be found:

- Industrial – food and beverage, energy exploration, pharmaceutical, dry cleaning, manufacturing, farming and agriculture

- Mid-sized to Small Businesses – manufacturing facilities and machine shops, automotive repair shops, construction sites, medical and dental services, roofing, marine, entertainment, ski hills, woodworking, auto body shops

- At Home or Home Located Businesses – pneumatic tools and workshops, airbrushing, vehicle repairs, cleaning with air pressure, inflating tires, blowing up balloons

How Can Compressor Efficiency Be Improved?

Fouling, erosion, and corrosion frequently occur in compressor components that are uncoated. Fouling accumulates on the surface of airfoils and reduces your compressor’s efficiency. Erosion and corrosion result in material loss and pitting which leads to the premature replacement of a compressor’s vital components. Coating the components of your compressor will help to eliminate these detrimental effects and improve the efficiency of that compressor.

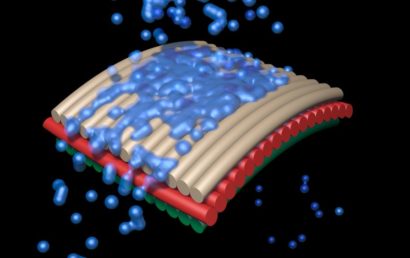

Metallic – Ceramic Coatings

When light erosion or corrosion must be resisted, and a fine surface finish is wanted or needed, metallic ceramic coatings can be used. The benefits of these types of coatings are as follows:

- Low-Cost Application

- Surface Finish Restoration

- On Large Components, Exhibit Versatility of Use

- Capabilities of Corrosion Protection

This kind of coating technique is generally beneficial to any number of components. This includes but is not limited to shrouds, guide veins, diaphragms, and rotating and stationary compressor blading.

Resistance to Corrosion

Various coatings can be used to discourage corrosion on parts which are susceptible to this type of condition. They are designed to improve corrosion resistance and surface finish. Some are specifically made to not only resist corrosion but provide release characteristics that will reduce particulate fouling.

For decades, A&A Coatings has been providing thermal spray solutions individually customized to various industries. We will assist you in your endeavor to maintain your compressor’s efficiency by protecting it against the detrimental effects of fouling, erosion, and corrosion. Call or email us today to find out how we can be of service to you, your company, and your industry.