Industry Spotlight: Industrial Machinery

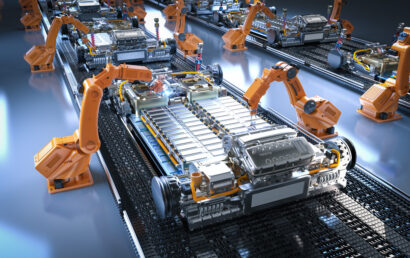

The industry of industrial machinery is a wide-ranging one, indeed. Numerous other industries use industrial machinery, after all. Between improvements in old industrial equipment and new, state-of-the-art industrial equipment, there is more machinery on the face of this earth and one can even imagine. One thing they all have in common, however, is that thermal spray protective coatings are not only used, but needed in many cases for safe, proper, prolonged usage.

Across varied industries, this cutting-edge machinery requires very specialized coating processes. And that’s where thermal spray coatings, and A&A Coatings specifically, come in.

Industrial Machinery and Coating Services Offered

As suggested, numerous industries are served by the industrial machinery market. And, as also suggested, one of the biggest concerns for that machinery (and things that they have in common) is to increase their lifespan by helping them to run better, longer. In order to achieve this, components being used in today’s industrial machinery must have certain characteristics. These are as follows:

- Wear resistance

- Abrasion resistance

- Corrosion resistance and more

Coatings Used For Wear, Abrasion, and Corrosion Resistance

Very specific coatings are used to increase the resistance on/of parts and components used in different machinery. Thermal spray coatings used for this purpose are as follows:

- Tungsten Carbide – This coating is usually applied through either a plasma spray process or HVOF. Among all protective coating materials, tungsten carbide offers the highest level of wear-resistance. If a particular mixed material is exceedingly hard or heavy, the coating process will likely employ tungsten carbide. The reason for this being that, compared to what is achieved by other materials, this coating process must be tougher.

- Aluminum Oxide Ceramic – One extremely dense plasma spray coating is the aluminum oxide ceramic, or white alumina. For most industrial and mixing machinery applications, superior abrasion and corrosion resistance is offered here. When one of the major concerns is contamination, this coating is favored due to the fact that it is a high-purity material.

- Chrome Oxide Ceramic – PTFE, or chrome oxide ceramic, may be used as a top coating layer. When it is used, the application results in a release surface that is smooth and highly slippery. Where is chrome oxide ceramic usually used? Generally, applications that deal with mixed materials which have a tendency to bind or stick to the components of the particular machinery being used are an ideal place for thermal spray coatings of chrome oxide ceramic.

Methods of Application

Several methods of application can be used when protective coatings are needed. These can include the following:

- Cold spraying – a high kinetic, non-heated process.

- Electric wire arc spraying – with one of the fastest coating rates, this process is economically efficient.

- HVOF (high velocity processes) – in a combustion chamber, oxygen and fuel are combined, then introduced to a powder, and finally sprayed onto a workpiece.

- Plasma arc spraying – a large array of materials is used in a process that creates a high-density coating through the introduction of powder into a heated plasma gas stream.

At A&A Coatings, our high-quality protective coatings have been used to guard industrial machinery components for over 70 years. We use the latest state-of-the-art equipment and keep up with the industry’s ever-changing requirements. If your industry or business has a particular problem that you would like addressed, contact us today to discuss further what our thermal spray coatings can do for you and your machinery.