Parylene Conformal Coating: What You Need To Know

Parylene conformal coating is a thin, transparent film used to protect sensitive components from moisture, chemicals, and temperature shifts. It’s applied in a vapor form, which allows it to coat even complex surfaces evenly. This technique is popular in aerospace, medical, and electronics industries where reliable, long-term protection is needed. Unlike other coatings that may pool or leave gaps, parylene sticks to surfaces with precision. That’s one reason it continues to grow in demand.

How Parylene Coating Works

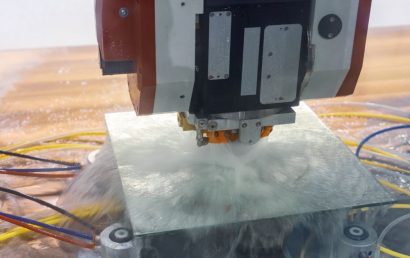

Parylene is applied using a vapor deposition process inside a vacuum chamber. The raw material turns from solid to gas without becoming a liquid. This allows the gas molecules to wrap around every part of the object being coated. As the vapor cools, it bonds tightly to the surface and forms a clear, pinhole-free layer. The coating is dry and ready as soon as it leaves the chamber, with no extra curing or drying needed.

Applications in Demanding Industries

Parylene coatings are widely used in industries that require reliable protection in small spaces. In medical devices, it shields implants, sensors, and catheters from body fluids and heat. In electronics, it protects circuit boards from corrosion and static. Aerospace firms use it on sensors and wiring to resist temperature swings and high altitudes. Even automotive and industrial tools benefit from this level of protection in tight spaces.

Benefits of Parylene Over Other Coatings

Parylene is uniform, meaning there are no thick spots or gaps. It doesn’t add weight or change the function of delicate parts. The coating holds up in both high and low temperatures. It resists chemicals, water, and even some radiation. Unlike liquid coatings, parylene can reach every crevice of a component without dripping or pooling. This is especially useful for parts with sharp edges or hidden sections.

Key Features That Make It Unique

The film is extremely thin, often less than a human hair. Yet it performs well under pressure. It’s dry, clean, and free of contaminants. There’s no outgassing, which means it doesn’t release fumes later. It sticks to a wide range of materials—plastics, metals, glass, and ceramics. This makes it flexible for different uses without needing primers or extra prep. For products that must remain sterile or stable, it’s an ideal option.

Challenges to Consider

While Parylene offers many advantages, it’s not for every job. The process needs special equipment and trained technicians. Removing it is difficult, so changes after coating are not easy. It also takes time to apply, especially for larger parts. That said, the benefits often outweigh the time and cost. When performance matters most, this coating is worth the investment.

Choosing the Right Partner for Coating Services

Working with a knowledgeable partner makes all the difference. At A&A Coatings, we’ve spent decades applying precision coatings to parts used in aerospace, medical, and electronics markets. Our team uses advanced methods to meet strict industry standards. From preparation to final finish, each step is handled with care and technical skill.

Why Parylene Might Be the Protection You Need

Parylene conformal coating offers reliable, lightweight protection for parts that can’t afford to fail. It helps extend product life in tough environments, with a finish that stays clear and thin. If your coating application involves moisture, heat, or chemicals, this might be the right choice.

Get in touch with A&A Coatings to learn how our thermal spray and advanced coating services can support your project goals.