Repairing Components With Spray And Fuse Coatings

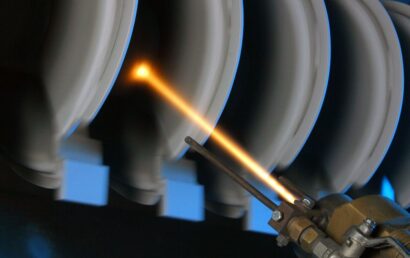

Thermal spray practices are on the rise with today’s growing emphasis on environmental advocacy. Creating less waste is being coupled with saving money in the eyes of many manufacturers. Out-of-service parts can be refreshed, revitalized, and rebuilt with thermal spray. Rather than replacing parts with new ones, old ones can be repurposed. For these repairs, standard mechanically bonded thermal spray may not be the smartest option. Rather, spray and fuse coatings might be the best repair method.

But why?

Craftsmanship and Technology

Though not outdated yet, spray and fuse coatings are nothing new. When applied in just the right situations, it has untold benefits. It perfectly couples the high-stress wear characteristics of hardface weld overlays with the ease of thermal spray. Expert knowledge and precision are required for technicians using spray and fuse, however. A reputable coating company is always recommended.

Spray and Fuse Coatings Lessen the Possibility of Wear

Very high bond strength is achieved with spray and fuse because it creates a metallurgical bond between the part and the spray and fuse coating. What this means is that the surface’s metals and the coating’s metals intermingle. For a longer period of time, coated parts can withstand more wear. A coating without voids is produced by the fusing of metals.

Compared to hardface weld overlaying, the wear characteristics of spray and fuse are similar. In fact, spray and fuse can use some of the same metals used in hardfacing.

Protection Against High Heat

In high wear and high-stress situations, spray and fuse is especially effective. Larger parts are particularly spray and fuse compatible due to the processes’ high heat. Without distorting, high heat is better withstood by larger sizes. On the other hand, though prior to processing they must be correctly engineered, spray and fuse can be used on small parts as well.

Temperatures similar to welding are used for the spray and fuse process. Parts that can particularly benefit from this process are as follows:

- Pump Pistons

- Sucker pumps

- Exhaust fans

- Augers

- Valve balls, and more

Bonding Strength of Spray and Fuse Coatings

The bond between the substrate of a part and the coating being applied is increased when high heat is used through spray and fuse. Similar to welding, self-fluxing alloys are typically used. So, spray and fuse can achieve a metallurgical bond between base materials and the coating metals. Required, however, is an in-depth knowledge of previously applied coatings and the base material. For a particular project, the proper techniques and metals must be chosen.

The sales team at A&A Coatings has experience and engineering knowledge to help you pick the proper coating process and the best coating for your needs. Extensive training and know-how are possessed by every one of our technicians in the area of thermal spray and all that goes with it. This is where high-quality workmanship and technology come together.

Contact us today if you’d like more information on thermal spray coatings and what they can do for your business, or about how they are already being used in your industry. Shorten downtimes, lessen maintenance costs, and improve your overall bottom line with the appropriate thermal spray.