The Stainless Steel Powder Coating Process Explained

The powder coating stainless steel process is a finishing method that adds both performance and visual appeal to metal products.

Powder coating involves applying finely ground particles of pigment and resin to a metal surface and then curing those particles into a solid layer that resists wear and corrosion. While stainless steel already resists rust and corrosion on its own, adding a powder coat can expand its usefulness by enhancing its finish and durability.

Why Powder Coat Stainless Steel?

Stainless steel is widely used because of its strength and natural resistance to oxidation, which makes it ideal for both indoor and outdoor applications.

Powder coating can add a layer of color and resilience that traditional stainless steel cannot offer by itself. The coating forms a uniform barrier that resists scratches, fading, and wear from everyday exposure, which is especially helpful in environments where visual appearance and protection are both important.

In addition to durability, powder coating stainless steel unlocks aesthetic options that bare metal cannot achieve. With virtually unlimited color and finish choices, powder coating allows products to match design specifications or branding needs while maintaining excellent performance characteristics.

Surface Preparation Sets the Stage

The first step in the powder coating stainless steel process focuses on surface preparation. Even though stainless steel is corrosion-resistant, its smooth surface naturally repels coatings, and contaminants like oils or dirt can interfere with adhesion. The surface must be thoroughly cleaned and degreased to remove any residues that could cause defects later.

Often, mechanical abrasion or bead blasting is used to create a slightly rough profile on the metal. This additional texture increases the surface area for the powder to grip, helping to ensure a strong bond between the stainless steel and the coating. Proper preparation improves the longevity and uniformity of the finish.

Sometimes a primer is applied after cleaning and abrasion. Certain primers are formulated specifically for stainless steel and enhance adhesion while contributing to corrosion resistance. This step is especially useful when the stainless steel will be exposed to harsh conditions.

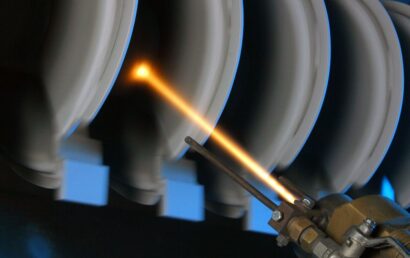

Powder Application Through Electrostatic Spray

Once the surface is prepared, the powder coating stage begins. In this step, dry powder particles made from polymer resins and pigments are electrostatically charged and sprayed onto the stainless steel. Because the powder particles carry an electrical charge, they naturally adhere to the grounded metal surface, creating an even coating.

Skilled technicians apply the powder in a controlled environment to ensure full and consistent coverage, paying attention to corners and recesses where adhesion is more challenging. This method produces a thick, uniform layer without runs or sags that can occur with traditional liquid paints.

Curing Transforms Powder Into a Durable Finish

After the powder is applied evenly, the coated stainless steel enters a curing phase in a controlled oven. Under heat, the powder melts, flows, and then undergoes a chemical reaction that forms long molecular chains. This transformation produces a tough, continuous surface that bonds tightly to the stainless steel.

Curing temperatures and times vary depending on the powder formulation and the part being coated, but this stage is essential for achieving the mechanical and protective properties that powder coatings are known for. As the coating cures, it forms a resilient surface that resists chipping, abrasion, and environmental stresses.

Professional Powder Coating Services from A&A Coatings

At A&A Coatings, we understand that powder coating stainless steel requires both technical expertise and quality materials to achieve results that last. Our technicians prepare and coat stainless steel using advanced techniques that promote adhesion and longevity, tailoring each project to performance demands.

With our decades of experience and a full range of finishing options, we offer results that offer superior protective strength and aesthetic versatility. Contact A&A Coatings today to discuss how we can enhance your stainless steel components with professional powder coating services that stand up to real-world use.