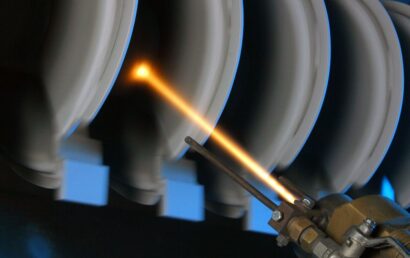

Thermal Spray Process Showcase | Flame Spray

A&A Coatings is a leading expert in the thermal spray coating market and we have the capabilities to carry out the most common thermal spray processes that are used to engineer surfaces for a wide range of applications. One of our fortes is to use the flame spray method (sometimes known as combustion spray) to produce spray and fuse coatings for many different industries. In this process showcase, we will talk about the flame spray process.

What is Flame Spray?

To understand this process, you need to know the feedstock materials you are referring to. For example, is it wire, powder or rod? The flame spray method uses combustible gases to generate energy to melt the material in question. The most common fuel gases used for this process include natural gas, hydrogen, propane, and acetylene in conjunction with oxygen. This method is not the same as the processes that uses an electrical source to heat or melt the feedstock materials, for example, in the electric arc spray process.

The great thing about the flame spray method is that the substrate will not experience any distortion during the coating procedure. Another thing we love about the flame spray process is that you can use virtually any material to be sprayed into the intended surface. The flame spray’s application time is fast and therefore can help you save costs.

What Types of Materials Can You Choose for the Flame Spray Process?

If you request for the flame spray process, you can then choose any types of materials you desire that feature melting points under 5500°F. Some of the most common flame spray materials are:

- Stainless steel

- Aluminum

- Low carbon steel

- Nickel-based materials

- Zinc

A&A Coatings has a wide spectrum of materials you can select for the flame spray process. If you do not know which material you should choose for your flame spray coatings, our material engineers will guide you based on the parts you want to coat.

Industries that Often Use Flame Spray Coatings

There is a long list of industries that make use of flame spray coatings which include agriculture, petrochemical, aerospace, machine repair and more. As long as the surface properties you seek involve impact resistance, corrosion resistance and wear resistance, you can certainly consider using the flame spray process. If you need ceramic or metallic coatings on surfaces that are prominent in less demanding environments, flame spraying is also ideal for your industry.

Choose the Flame Spray Process for Your Coatings Today!

A&A Coatings has a top range of industrial grade flame spray equipment to carry out this process. We also have more than 70 years of expertise and industry experience to help you achieve any type of thermal spray coatings that you desire. Our dedication to our customers is second to none and with our competitive pricing, it is no secret why so many industries that are looking for flame spray coatings are working with us.

Give us a call today and let us put our experience and resources to work for all of your needs!