4 Key Advantages Of Using Ceramic Coating For Stainless Steel

If your equipment or components face heat, wear, or chemical exposure, stainless steel ceramic coating can help you extend the life of your parts. This coating creates a durable surface that resists friction, abrasion, and corrosion while maintaining the strength and appearance of stainless steel.

Understanding how these coatings work makes it easier to reduce maintenance demands and improve long-term performance. Whether you are repairing worn parts or upgrading new components, using stainless steel ceramic coating is a smart approach for keeping your equipment operating smoothly. Below are the key advantages of applying ceramic coating to stainless steel components.

Enhanced Durability and Wear Resistance

Stainless steel ceramic coating improves the durability of metal surfaces by providing a hard layer that resists abrasion and friction. Stainless steel is already resistant to corrosion, but adding a ceramic coating allows your parts to handle heavy use without degrading quickly.

Components exposed to repeated contact or pressure last longer when coated because the surface is protected from wear and material loss. For your operations, this means fewer repairs and replacements and less downtime. A&A Coatings applies coatings with precision, so your stainless steel surfaces can handle demanding conditions while maintaining their performance over time. These coatings help parts maintain their structural integrity during prolonged use.

Protection Against Corrosion and Chemical Damage

Ceramic coatings on stainless steel provide an added layer of protection against chemical exposure and environmental damage. Even though stainless steel resists rust, chemicals, and extreme conditions can cause gradual deterioration. Applying a ceramic coating reduces the risk of corrosion by creating a barrier that keeps moisture, acids, and other substances from reaching the metal.

This added protection extends service life while reducing routine maintenance demands. Parts used in processing plants, chemical manufacturing, and marine applications benefit from this type of protection.

Improved Thermal and Mechanical Performance

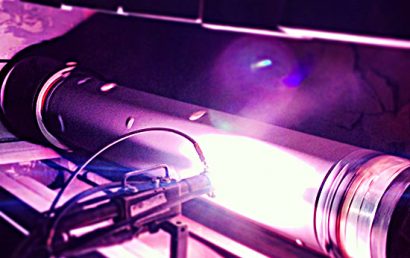

Adding a ceramic coating improves the way stainless steel components handle heat and mechanical stress. Coated parts are better able to operate at higher temperatures without warping or weakening. They also maintain their shape and function under pressure or heavy loads. This is important for components in engines, turbines, or industrial machinery where heat and force are common.

As a result, parts perform more consistently in high-stress environments. A&A Coatings applies coatings carefully to provide a uniform layer that balances thermal resistance with mechanical durability, helping your equipment continue working effectively and consistently.

Cost Efficiency and Reduced Maintenance

Coated parts have an extended service life because they resist wear, corrosion, and heat damage. This reduces the need for repairs or replacements and keeps your operations running smoothly. You can avoid unexpected downtime and production delays while also saving money by prolonging the life of your equipment.

Protect your equipment today with advanced stainless steel ceramic coating. At A&A Coatings, we combine thermal spray services with in-house machining and finishing to extend the life and improve the performance of your parts. These capabilities help your equipment operate longer and more efficiently by providing durable protection against wear, heat, and corrosion. As a result, you experience fewer interruptions, lower maintenance costs, and reduced downtime across your operations.