How To Measure Conformal Coating Thickness Accurately

Accurate measurement of conformal coating thickness is fundamental to maintaining performance, reliability, and long-term protection of critical components. Knowing how to measure conformal coating thickness allows you to verify that each layer provides the right insulation and resistance without excess buildup. A thin film can expose circuits to moisture and corrosion, while an overly thick one may lead to cracking or poor adhesion. Achieving balanced results begins with using the right equipment and precise measurement techniques.

Understanding Coating Thickness

Conformal coating thickness refers to the measured depth of a protective film that shields components from moisture, dust, and environmental stress. It typically ranges from 25 to 250 microns, depending on the coating type and application. A consistent film thickness allows for electrical insulation without trapping heat or introducing mechanical stress. Inaccurate measurements can cause coating failure or rework, leading to increased costs. Precise measurement keeps production within specification and helps achieve the expected level of durability and performance.

Common Measurement Methods

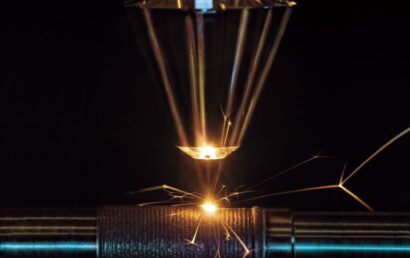

Several reliable techniques are used across industries to measure coating thickness, each suited for different materials and part shapes. Wet film gauges are often used before curing to record the applied layer and predict its final dry thickness. Eddy current probes provide a non-destructive way to assess coating depth on metallic substrates by detecting variations in magnetic response. Ultrasonic testing works well for non-metallic components since it measures the travel time of sound waves through the coating to the substrate.

For validation or laboratory inspection, micrometer readings and optical approaches such as confocal microscopy or interferometry help verify precision. These techniques support accurate assessment of coating uniformity, even on parts with intricate surfaces. Choosing the right method depends on coating type, substrate composition, and the level of measurement precision required. Each approach contributes to reliable quality control throughout production.

Maintaining Accuracy in Real-World Applications

Accurate thickness measurement depends on preparation and consistency throughout the process. Calibration using reference samples or coated coupons should be performed before taking any readings. The measuring probe or gauge must rest evenly on the surface, as tilted placement can distort results. Multiple readings across different areas of a board or component help identify uneven application and improve reliability. Coatings with varying densities may require conversion between wet and dry measurements, especially when the solids content affects the cured film. Factors such as temperature, substrate roughness, and operator technique can influence accuracy. Controlling these conditions supports repeatable, verifiable measurements that meet quality and performance goals.

Precision You Can Trust

Accurate measurement defines how well coatings perform over time. At A&A Coatings, our expertise extends beyond thermal spray applications to include plasma spray, HVOF coating, and surface restoration services designed for high-performance and precision-critical industries. We also conduct thickness verification and surface preparation to maintain coating uniformity and adherence to exact specifications. Our decades of technical experience help clients achieve measurable, repeatable results across complex components.

Ready to discuss a coating solution tailored to your project? Contact us today to consult with our technical team.