Applying Chromium Oxide Coatings Via Plasma Spray Technique

Industry leaders have long tasked their development and research teams to create coatings that are wear resistant. Numerous industries benefit from coatings that can tolerate an environment that is corrosive, such as that offered by solvent-based inks, chemicals, and even water under the right circumstances. Additionally, when surfaces roll together or rub against each other, abrasive wear occurs, as well. The chromium oxide coatings used today create ceramic, hard surfaces which stand up better to any number of threats.

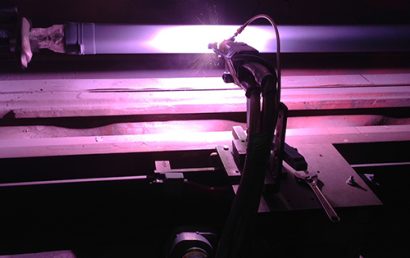

The process of applying chromium oxide coatings using a plasma torch involves injecting powdered coating material into the torch. Through an arc, this powder passes while a plasma flame produces heat. The coating material is melted by this heat which allows it to better adhere to the desired soon-to-be-coated parts.

Chromium Oxide Coating’s Plasma Torch

Used to apply a coating, the plasma torch is named for the ionized gas – gas plasma – that it uses. To an anode or nozzle, nitrogen gas flows through the torch. With a welding power supply, it is positively charged. Positioned near the anode in the gas stream, a cathode creates an electrical arc by being connected to the negative side of the power supply. Through this high energy arc, the gas flows and ionizes. The resulting heat produces great pressure because it makes the gas expand. Through a nozzle opening in the anode, this pressure escapes, forming a high velocity stream of expanding, hot, plasma flame.

What’s So Great about Chromium Oxide Coating?

No matter what industry uses chromium oxide coatings, there are few things not to love about all its benefits. It is hard, corrosion resistant, offers a high bonding strength (to the surface of whatever part it is applied to), and offers a smoother coating surface than many other coatings.

- Hardness – On the Vickers scale, chromium oxide measures 1300 on average. In an operating environment, greater wear resistance is created by greater hardness.

- Bonding strength – Increased bonding strength means that even in the most demanding applications, this coating will stay in place. From solvent or water that would otherwise weep through a more porous coating, it protects the surface beneath in a manner that discourages coating bond failure.

- Smoother surface coating – The resulting surface is smoother thanks to the low porosity. To meet the stringent expectations of numerous industries, this coating offers corrosion resistance and a hard surface while retaining all the benefits of the desirable properties held by chromium oxide.

The Medical Industry and Chromium Oxide Coatings

Though numerous industries throughout the world make good use of chromium oxide coatings, they are used on a regular basis in the medical industry. These coatings are applied to orthopedic implants such as hip replacements. It helps to discourage rejection and allows medically inserted parts to last longer.

Uses in other industries:

- To seal equipment surfaces (this is of particular significance in the food processing industry).

- Where seals are used, this coating can enhance their properties.

- Wear and abrasion resistance are increased through the use of this coating.

- Where bearings are used, this coating offers added protection.

We Offer a Large Selection of Coatings

At A&A Coatings, through the use of a variety of thermal spray processes, we specialize in different types of thermal spray coatings. Chromium oxide coatings are just one example of what we have to offer businesses. With our coatings, you can protect your parts and machinery, lessen downtime, reduce maintenance costs, and improve your bottom line. Call or email us today to find out more about utilizing the chromium oxide coatings for the protection of your surfaces!