Nano Ceramic Coatings Vs. Sprays

Nano ceramic coatings and ceramic sprays are two popular protective coating choices. Both are known for their durability and performance. While it’s true they share similarities when it comes to composition, application, and benefits, there are important differences that help to distinguish these two coatings. Let us look at the differences between nano ceramic coatings vs. sprays in this article.

Understanding Nano Ceramic Coatings

Nano ceramic coatings, also known as ceramic paint coatings, charge liquid polymer solutions with ceramic nanoparticles. When applied to surfaces like automotive paint or industrial equipment, these coatings create a protective layer. It bonds with the substrate at the molecular level.

Nano ceramic coatings provide outstanding durability, scratch resistance, UV protection, and water-repelling properties. They last several years with proper maintenance due to their known longevity.

Exploring Ceramic Sprays

Ceramic sprays usually refer to spray-on ceramic coatings. They are applied using aerosol cans or spray guns. These sprays contain ceramic particles suspended in a carrier liquid (like water or solvent).

When sprayed onto surfaces, the carrier evaporates. That leaves behind a layer of ceramic particles that bond with the substrate. Some prefer ceramic sprays for their easy application and affordability. They offer a cost-effective alternative to professional-grade nano ceramic coatings.

Different Kinds of Ceramic Thermal Spray Coating

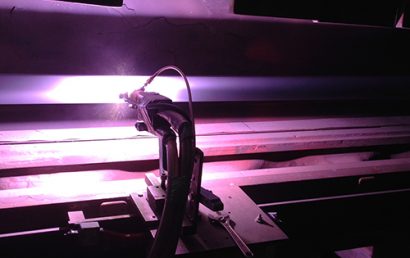

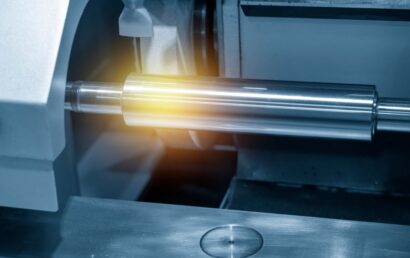

In addition to liquid nano-ceramic coatings and ceramic sprays, there are ceramic thermal spray coatings used in industrial applications. Thermal spray processes involve melting or heating ceramic materials such as oxides, carbides, or nitrides, and spraying them onto surfaces using specialized equipment.

These coatings are applied in layers and offer excellent wear resistance, corrosion protection, and thermal insulation. Common types include plasma spraying, flame spraying, and high-velocity oxygen fuel (HVOF) spraying.

Maintaining Ceramic Coating

Both nano ceramic coatings and ceramic sprays require proper maintenance to preserve their effectiveness and longevity. Regular cleaning using gentle car wash soaps or cleaning solutions designed for coated surfaces is necessary to avoid damaging the coating.

Refrain from using abrasive cloths or harsh cleaning tools that can scratch the coating. Nano ceramic coatings may require periodic reapplication to maintain optimal performance, while ceramic sprays may need more frequent touch-ups due to their thinner application.

Nano Ceramic Coatings Vs. Sprays: Choosing Between the Two

The choice between nano ceramic coatings vs. ceramic sprays depends on specific needs and preferences.

Nano ceramic coatings offer superior longevity and durability compared to ceramic sprays, making them perfect for long-term protection in demanding environments. Ceramic sprays are easier to apply and more budget-friendly for DIY enthusiasts or routine touch-ups.

Overall, both nano ceramic coatings and ceramic sprays provide effective protection and improvement for various surfaces. Understanding the differences between these coatings allows consumers to make the best decisions based on their specific needs and preferences, providing optimal performance and protection for their valuable assets.

Think about the performance requirements, cost considerations, and application ease when selecting the right ceramic coating for your project.

Ceramic Coating Pioneers: Unmatched Expertise and Innovation

For over 70 years, A&A Coatings has been pioneering ceramic coating solutions that are unmatched in the industry. As a facility dedicated solely to thermal spray coatings, we have cultivated unrivaled mastery in the application of ceramic, metal, cermet, and hard-faced coatings.

Call 888-725-0150 today or use our online form to experience the quality and innovation that define our ceramic coating leadership.