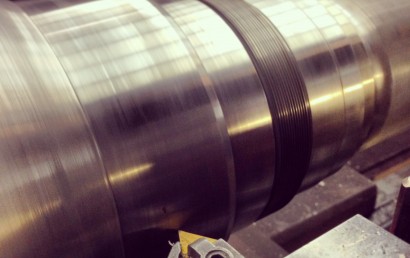

The Use Of Roll Grinding In Paper & Board Machines

All roll grinders are fitted with a machine bed in sandwich design. The advantages of these designs are excellent damping properties, thermostability, and much lower foundation costs.

The Precision of Roll Grinding Machines

Roll grinding machines bear advanced levels of speed, precision, and efficiency. The user-friendly module, designed for roll grinders, performs exact machining output. The blending of the rapid controls with cutting-edge measuring machines enables all corrections to be performed on demand: adjustments get completed during all machining operations, while extra machine cycles are not further needed.

The Function of Role Grinders

Grinders with traveling tables combine high precision, mechanical inflexibility, damping, and advanced measurement functions or control technology. The heavy ribbing assures the strength of these machines. Blending hydrodynamic or hydrostatic principles enables excellent precision with a durable service period. Symmetrical load division leads to full thermostability.

Measuring and Inspection Systems

High-quality measuring technology forms the basis for precisely moderating machine grinding processes and is crucial to getting ideal grinding outcomes. Grinders provide accurate measurements and inspection functions.

C-Frame

The C-frame measurement gauge assesses the roll geometry with a frequency of one µsec. Every second, 1,000 assessed measurements get registered, evaluated, and processed are measurement probes placed facing the grinding wheel’s core for exact images of the present grinding position of the workpiece may be shown.

Ultrasonic Inspection

Manufacturing faults in the roll or the energy depletion from operations within the mill may get screened over a distinct operating ultrasonic inspection. The ultrasonic examination screens potential fractures beneath the roll surface/on the barrel reaching to the depth of 250 mm. Standard ultrasonic technology examines combined cast rolls in which critical transition spans across the shell with the center of the registration.

Roll Surface Inspection System

The Roll Surface Inspection System records or registers the reflections of the laser beams upon the roll surfaces. Special image assessment software screens or reveals roll surface errors like chatter marks or feeding lines, commas, and overall composition while identifying the locations. The machines alternatively screen errors happening merely once.

Basic Turning Device

The turning device gets placed upon the grinding crown instead of the grinding spindle. This is especially suitable for machining coated paper rolls. With warm rolling mills, these are more suitable for turning edger rolls with roughing tables.

Turning Device for Heavy-Duty Machining

The grinders may be installed with a particular turning saddle on the machine’s rear ends to attain a higher quantity of stock clearance.

CBN wheels

The grinding technology utilizes CBN wheels in collaboration with an Austrian grinding wheel manufacturer Mach Rotec. The mixture of grinders, HCC/KPM, controls with measuring tools, and Mach Rotec grinding wheels enables secure and repeated grinding output.

MACH technology reduces time wastage by fulfilling better stock cleaning with less grinding time. Improving stock cleaning may extend roll service longevity. Other benefits include enhanced efficiency for machines.

Automation

Roll grinding for paper machines is performed through automation systems. The paper machines for roll grinding should be fitted with updated CNC machine controls. These customized services render every grinder unique.