Thermal Spray Coating Vs. Painting: Which Is Better?

Corrosion, abrasion, wear and tears are some of the things lowering the efficiency of industrial parts these days, hence the need for coatings. Coatings offer protection to these components and make them highly resistant to any external interactions. There are various types of coatings available; topping the list are thermal spray and traditional painting.

People often compare thermal spray coating vs. painting to know which is the better option. Here are a few differences between the two coatings to help you make an informed decision:

Thermal Painting

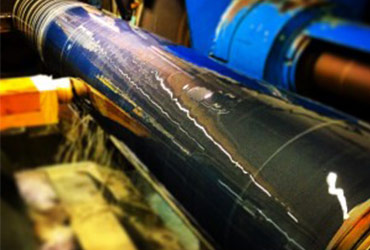

Thermal spray coating involves applying various coating materials using pressurized high-heat gas. The process enables the material to bond directly to the surface to form a coating enabling resistance against corrosion, lubricity, thermality, and other elements. Although there are many options, thermal spray coating stands out because of its speed and widespread usage.

The main tool used for the process is a spray gun, which can be operated manually or automatically. These coating materials can include alloys, metals, ceramics, plastics, and carbides.

Painting

This is the traditional form of coating industrial parts and other components to enhance corrosion resistance. Most painting materials include organic bases, inert fillers, corrosion-resistant compounds, and metal particles. The coating can be applied to surfaces by brushing, dipping, or spraying.

Paint systems come in different layers, which include a priming coat, a top coat, and primary protective coats. However, painting has a shorter lifespan compared to other coatings like zinc, aluminum, or even thermal spray.

Cost

The initial painting cost is relatively low compared to thermal spray coating. However, the painted surface might not last more than five years before needing a repaint. On the other hand, thermal spray coating has a relatively high initial cost; however, it can last more than 20 years.

Even though thermal spray might seem expensive, it is a good idea to choose this option since you won’t have to spend much on the coating for a long time. When you consider the cost of repainting in 20 years, you will find that thermal spray coating is cheaper in the long run.

Volatile Organic Compounds

Paint is made from materials containing different volatile organic compounds. These compounds constitute more than 65% of the paint. After drying, these compounds are very harmful and will evaporate out of the paint into the atmosphere. However, thermal spray coatings comprise materials like alloys, metals, and ceramics that do not contain these compounds. In other words, thermal spray coating is better for the environment as compared to painting.

Application

The thermal spray coating process can occur irrespective of the atmospheric conditions. The materials in the thermal spray can be applied at any level of temperature or humidity. However, paint-based coatings cannot be applied at any temperature and are season-based.

Time

An additional benefit of using the thermal spray coating is that it has no cure time. Once the spraying is completed, the assets can start operating. However, painting needs a cure time before you can start using the assets, which is a major drawback.