Thermal Spray Coatings From India Of Interest To NASA

Officials from Nassau are reporting that their scientists are interested in new technology using thermal spray coatings on spacecraft gas turbine engines. A Dr. Satish Tailor was recently contacted by one NASA scientist in particular, James L. Smialek. According to MEC (Metallizing Equipment Company) chairman SC Modi, the contact occurred after Ceramics International and Thermal Spray Bulletin published an article regarding the new technology.

YSZ – Yttria Stabilized Zirconia

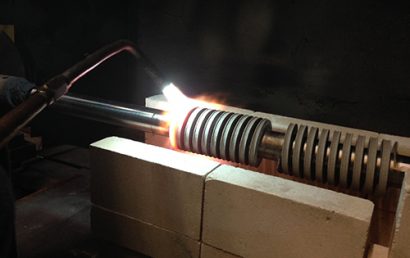

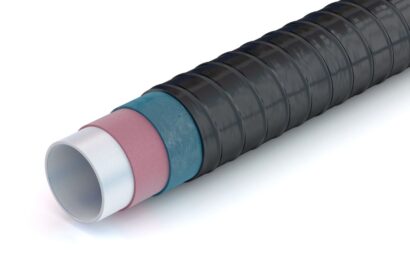

Introducing a new plasma sprayed coating technology: YSZ. This controlled segmented technology was developed by Dr. Tailor, an R&D (research and development) chief scientist at MEC. According to the doctor, YSZ can cut the cost of thermal spray coating by nearly 50%.

The doctor explains that applications used in spacecraft, such as gas turbine engines, benefit from the coating’s segmentation (vertical cracks). But here’s the problem… Through a very expensive process, these types of cracks are currently being developed by researchers, and the costs are outrageous. These pricy processes include EB-PVD or SPS deposited coatings. In addition to being costly, using the current processes, these cracks are not controllable when generated during the coating deposition process.

Thermal Barrier Coatings That Are New and Improved, Yet Inexpensive

What was most important here was the survival of APS (atmospheric plasma sprayed) produced YSZ thermal barrier coatings at a superior level. Dr. Tailor produced a solution that not only has the potential of wider strategic/industrial acceptability but was inexpensive (particularly when compared to the old methods).

Outside Sources Show Interest

After the Nassau scientist contacted him, Dr. Tailor shared his research. Other leading research organizations in the country, after reviewing this new technology, were equally impressed. Two organizations, in particular, are the DRDO (Defense Research Development Organization) and the CSIR (Council of Scientific and Industrial Research).

A Promising Future

APS based business could definitely benefit from the international patenting of the equipment involved in this new and improved process and the process itself. It shows great promise in the affordable generating of vertical cracks. According to scientists, if a stain tolerant coating can be developed through industrial adaptation, this new process, particularly when compared to techniques that are more expensive, will definitely be more economical.

Who Is Dr. Tailor?

Dr. Taylor originally hails from Jaipur. He has published more than 25 international and national research papers about thermal spray technology in reputed journals. The doctor’s metallurgical engineering Ph.D. was completed at Jaipur’s MNIT (Malaviya National Institute of Technology). He specializes in plasma spray coatings.

Dr. Tailor is the Journal of Thermal and Engineering chief editor, and the Journal of Materials Science and Surface Engineering deputy editor-in-chief. As a visiting young scientist, he is also associated with Russia’s NUST (National University of Science and Technology).

At A and A Coatings, we do everything we can to stay abreast of current changes in the world of thermal spray protective coatings. We apply the latest proven technology and can assist industries in reducing maintenance costs, lessening downtime, and extending the life of their components and machinery. If you would like to find out more about what thermal spray protective coatings can do for you and your company, contact us today.