What Does A Thermal Spray Operator Do?

Have you wondered what thermal spray operators do or how they earn their job title? Here you will learn more about Thermal Spray Operator training and understand how they are capable of working with so many different types of coatings and thermal spray equipment.

Qualifications & Prerequisites Needed to be a Thermal Spray Operator

The minimum prerequisites for a prospective operator to be considered include but are not limited to:

- Basic understanding of industrial safety;

- Basic technical understanding of manufacturing equipment and coatings; and

- Basic understanding of tool and gauge handling.

Training

Because A&A Coatings operates in accordance with MIL-STD-1687a we require all of our thermal spray operators to complete a rigorous training program before they are considered to be qualified. Once prerequisites are considered to be met, a prospective operator will accomplish the following training:

- Thermal Spray and OSHA Safety;

- 20 hours of Classroom training covering:

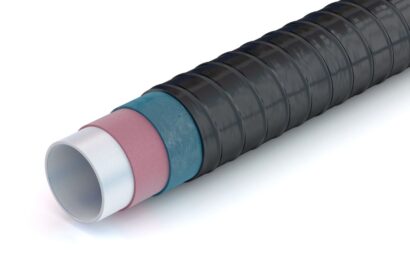

- General Thermal Spray Theory

- Basics of Coating Materials

- Basic Coating Physics

- Surface Science

- Thermal Spray Coating Process and Steps

- A&A Thermal Spray Practice and Standard Operating Procedures

- Specific on the job training on thermal spray equipment and coating processes:

- 80 Hours for Plasma Spray Coating

- 40 Hours for Flame Spray and HVOF Coating

- 20 Hours for Electric Arc Spray Coating

Testing and Examinations

Upon completion of training, prospective Thermal Spray Operators shall satisfactorily complete a written test covering the critical aspects of theory, applications criteria and aspects of the coating processes and equipment operation. Additionally operators are tested separately for understanding of A&A Coatings’ Standard Operating procedures. Lastly, all operators must apply coating on test specimens for each coating material for which they shall be qualified. These test specimens are tested visually, microscopically and for bond strength. Upon successful testing and acceptance of the results the operator is considered qualified to spray a particular coating material.

Key Qualities that a Qualified Thermal Spray Operator Should Possess

- Able to operate in conditions where high levels of electrical energy are present

- Able to properly handle and use both flammable and inert fuel gases

- Able to independently operate complex thermal spray equipment to carry out processes such as plasma spraying, HVOF spraying

- Able to independently operate manufacturing machinery such as lathes and traverses

- Very qualified and experienced operators have the capability to control and program robotic handling equipment

- Able to perform process tests for quality control and assurance

- Possesses exceptional communications skills to follow written/verbal instructions accurately and point out potential problems in advance

Understanding the Job Scope of Thermal Spray Operators

- Before actual operation, all thermal spray equipment must be set up in accordance with Standard Operating Procedures.

- Prepare parts for thermal spray coatings (blasting, masking, cleaning)

- Ensure thermal spray process is properly applied (to the correct part features) by interpreting and following process sheets

- Prepare parts for the next process by removing masking after required coating

- Spray coating samples for the purpose of process control, proof of competency, and qualification. This allows other process engineers to help improve the coating process

- Utilize dedicated handling equipment, clamps, and turntables to ensure safe parts processing

- Utilize handheld gauges for parts measurement during coating process (ensure the amount of applied coating is correct)

- Ensure the completion of important documentation such as environmental records, safety records, test records, and work performed that may apply

- Completing log books and performing daily checks to maintain equipment

- Adhere to all security, stock control, quality and safety policies when selecting, handling and applying coatings

At A&A Coatings, we have a robust team of well-trained thermal spray operators ready to service your coating needs. They are able to work and perform well in a wide array of thermal spray applications, including coatings for the aerospace, marine, industrial machinery industries. Contact us today to find out more about our thermal spray coating services!