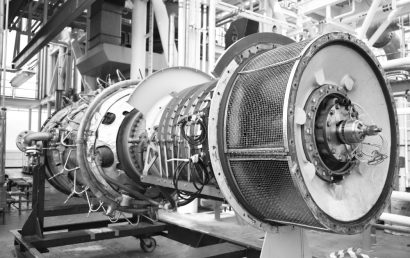

Understanding the Technical Process Behind Thermal Barrier Coatings

The protection of metal structural parts from elevated, extreme temperatures is specifically what thermal barrier coatings were designed for. They increase the lifespan of the part by reducing fatigue and stress. Lots of things go into thermal barriers in order for them to offer such a high level of protection – each adding to the protecting thermal properties. There are four distinct layers to each coat. A single boundary is made by each coating.

The Composition of Thermal Coatings

One ceramic layer paired with one metal layer is actually all that a typical thermal coating consists of. But wherever the coating adheres to a substrate, the bond can be compromised because of the mismatched thermal coefficients. In this case, the ceramic layer is assisted with adhesion by, between the metal layer and the substrate, a bond coat being employed. There can be a number of totally different layers involved in these styles of boundary coatings.

The Coatings

The bond coat is how the first layer for the coating is referred to. In forming a boundary, it plays an integral role because it is what allows the coating to bond to the substrate. It adheres the layer to the metal substrate and is made from a ceramic metallic composite. This metal coat is the primary preparation for the second coat (the ceramic chemical compound coating layer).

The ceramic final coat is the last layer of the coating. The substrate is protected by this final coat formed from YSZ (yttria-stabilized zirconium dioxide). The other coating layers are kept at a lower temperature than the surface by this last coat. They work together to protect each other and the substrate.

Bonding Layer Boundary Coating Advantages

There are many benefits to using a bonding layer for adhesion assistance. The coating offers exceptional wear resistance and ends up being much tougher. What results is a reduction of stress. Stress within the prime coat would otherwise be caused by chemical compounds expanding excessively. The boundary coating and thermal shock resistance are also accumulated throughout the process.

Either manually operated or mechanically operated spray instruments are used to apply the thermal barrier coating. To block out fumes, this is done in a specially designed enclosure. There can be electricity, high temperatures, fumes, bright light, noise, and more associated with the spray coating application. So that none of the debris gets trapped within the coating, an appropriate extraction process is essential. Additionally, to protect the technician, proper respiratory filters, masks, etc. must be worn.

Each and every coating has its own characteristics and precise application specs.

Thermal Spray Guns

The guns used to spray the coatings work on a power combustion system. Pressure, nonexplosive gases, and massive force are involved. The process is a very complicated one that should only be attempted by highly trained technicians for any number of reasons. These coatings frequently require very exacting measurements and a level of caution specific to the task at hand.

At A&A Coatings, technical processes and thermal spray coatings are our specialty. And they have been for decades. That’s why, when industries have questions about or need thermal spray services, they turn to us. Contact one of our friendly, helpful service representatives and find out what we can do for your company.