Withstanding Supercritical Carbon Dioxide Environments With Anti-Corrosion Thermal Spray Coatings

Anti-corrosion thermal spray coatings are being used to save the atmosphere. In some environments, carbon dioxide levels are a distinct concern. But through the use of today’s thermal spray technologies, better control over CO2 emissions can be achieved.

What Is CCS?

CCS stands for carbon capture and storage. It is a method of carbon sequestration that, when burning fuels that are carbon-based, minimizes CO2 (carbon dioxide) release into the atmosphere.

What must happen here, primarily, is that CO2 emissions must be captured. These emissions come from industrial process and electricity generation fossil fuels. Various resulting gases and CO2 must be separated. When needed, the CO2 will be compressed, transported, and then injected into storage sites. These sites can consist of saline aquifires or depleted gas and oil wells. The whole point is to isolate the gases from the atmosphere, long-term.

Just how much of CO2 emissions can be captured through CCS? Up to 90% of the emissions can be captured with this technology, according to the Association for Carbon Capture and Storage.

Problems Arise with CCS

There can be little doubt that industries would soon adopt CCS. But first, it had to prove itself to be viable, economically. When corrosion issues arose during wet, high pressure CO2 storage, transporting, and separating, the chances for industry adoption on a wide-ranging level was threatened. And, to add to the issues, depending on the process stage, differing corrosion concerns presented themselves. A solution was needed.

Thermal Spray to the Rescue?

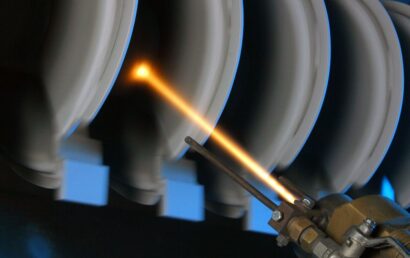

Experimentation that would hopefully lead to the solution was conducted using corrosion resistant alloy coatings that were thermally sprayed on carbon steel. The hope was that the combined structural integrity of carbon steel and the corrosion resistance of corrosion resistant alloy coatings would be an economical alternative to components that were fabricated in ways that were proving to be insufficient. With thermal spray coatings, without costly replacement, damaged CRA coatings can be repaired. Adequate repair means that reuse of a repaired component is possible.

What was discovered through experimentation was that a “cold spray” technique was preferable to obtain a denser coating. Additionally, this coating, as well as being dense, has a nearly nonexistent through-thickness porosity.

The Results of the Experiment

The resulting conclusion was that, in the case of certain infrastructures, for a corrosion mitigation method that is cost-effective, specific HVOF sprayed coatings are ideal. In addition to applying to infrastructures that may come into contact with H2S and supercritical, wet CO2, these coatings may also be used for the transport of impure CO2 as a pipe inner lining.

Naturally, care must be taken where any number of factors are concerned when dealing with these thermal spray applications. But when done expertly and correctly, the result is the solution that was needed in this situation.

At A & A Coatings, we are proud to be part of the technological advancements being made in any number of industries today. Thermal spray surface coatings are invaluable to almost every business on the planet, either directly or indirectly. If you would like to find out how thermal spray coatings can benefit your company or your industry, contact one of our knowledgeable, experienced staff members today.