Understanding The Difference Between Thermal Impedance And Thermal Conductivity

When selecting the TIM (thermal interface materials) for your application, an important aspect is knowing the ability (or inability) of the materials to transfer heat. This occurs courtesy of thermal impedance or thermal conductivity.

TIMs

In electronic components, TIMs (thermal interface materials) are useful for thermal management. The reason for this being that they take the heat moving from one heat generated component and enhance that transfer to a heat sink or heat dissipater.

On datasheets across the industry, thermal conductivity is frequently published by manufacturers in units of Celsius degrees- square inches, as well as Watts/meter-Kelvin. When selecting a TIM, how should you consider that information? In fact, between these two, what is the difference?

Thermal Contact Resistance and Thermal Resistance

Thermal contact resistance and thermal resistance must be understood before thermal impedance can be understood.

An inherent thermal property of a material is thermal resistance. How the flow of heat is resisted by a material of a specific thickness is measured by thermal resistance. Directly related to the resistance is TIM thickness. Thicker TIMs do not transfer heat as effectively as thinner TIMs.

The interfaces where the heat sink, heat generating component, and a TIM all meet together offer contact resistance specific to them. When in contact with the interface material, micro air voids are created by surface irregularities due to the fact that the components in question are never perfectly smooth or flat. Because air is not a good thermal conductor, these voids reduce heat transfer effectiveness.

Thermal Impedance

The sum of a material’s resistance and all contact resistances is referred to as the material’s thermal impedance. In a specific application, if a material is a better thermal conductor, that means that the material’s thermal impedance is lower. So, having a large impact on the thermal impedance of a material are factors such as interior thickness, presence of adhesive, clamping pressure, surface flatness, surface roughness, etc.

Therefore, specific to the application, because it accounts for more variables, thermal impedance is a better thermal property in a “real world” setting.

When, for a specific application, making comparisons between MITs, for the most general, beginning stages, you can use thermal conductivity. But for “real-world” conditions and the utmost accuracy, thermal impedance versus pressure data should be used.

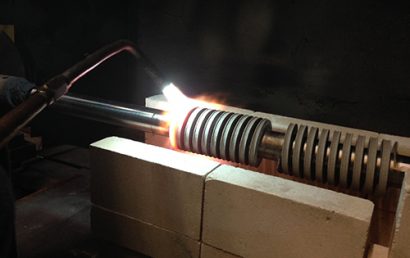

Thermal Spray Barrier Coatings

Thermal spray coatings are used to keep out various things or to rebuild or enhance a surface. When a thermal barrier coating is needed, a ceramic topcoat and a metallic bond coat are used as a thermal barrier coating. The processes that can be used to apply these coatings are as follows:

- Spray and fuse hard facing

- Metallizing

- Plasma spray coating

- HVOF coating

There is every possibility that these types of coatings have been used on components and parts throughout multiple industries to protect them against exceedingly high temperatures. Who would use thermal barrier coatings? This type of thermal spray coating can be used on aerial engines, gas turbine parts, and more.

At A & A Coatings, we offer coatings of every kind imaginable and service industries throughout the world. Whatever your dilemma, we have the thermal spray coating that can help protect your components, machines, surfaces, and – ultimately – your business’s bottom line. Contact us today if you have questions.